USE OUR SERVICE AND BENEFIT FROM OUR EXPERIENCE

We have been building and planning hydraulic presses and other industrial plants for almost 60 years. In the “after sales” area we maintain and service our plants and help our customers to permanently optimise the production process. Our oldest attended plant is a TOMRUK PRESS from 1974, which is now operating on the newest level.

You can benefit from this experience by using our service. If you have a problem with your industrial production plant, please contact us. We are also an experienced partner in the conversion to technology 4.0 and robot automation. Contact us and let us convince you of the quality of our service.

Service

OUR UNIQUE TOMRUK SERVICE CONCEPT IS EXPLAINED BELOW

Maintenance at the highest level and profitability

In order to avoid disruptions and breakdowns in production, it is advisable to have production systems and above all presses serviced at regular intervals. With us, you have a partner who conscientiously and competently subjects your plant to regular and extensive maintenance and provides quick and uncomplicated assistance in the event of a fault. Of course, all services are included in the purchase of a new press for 1 year, but we also offer our services for third-party products.

ADVANTAGES:

Quick spare part supply!

Digital access and error identification!

Minimum downtime, high quality and cost efficiency!

We find the optimal solution for you

If you have problems with your production plant or need support in planning a new plant, please contact us and we will support you. Due to our years of experience as a manufacturer of hydraulic presses and special production plants, we know exactly what is important. By using our industrial service you get everything from one source and this saves time and prevents machine breakdowns. During a consultation we take your problem and objectives into account and work closely together with your industrial architects and your preferred cooperation partners on an international level.

ADVANTAGES:

Everything from one source

Fast, uncomplicated and competent advice

Project planning of small and large projects!

From old to new – mechanical, technical and electronic revision of your plant

The modification of the control system of a production line or the implementation of new systems often makes it necessary to adapt the switch cabinet to the new conditions. This is also no problem for us and is a service we are happy to offer you. Also an adaptation of the switch cabinet to country-specific conditions is no problem for us.

ADVANTAGES:

Preparation Industry 4.0 Standard

Adaptation and optimisation of the control system

Revision of the hydraulics and mechanics of the plant

Retrofitting of safety functions such as saftey light curtains

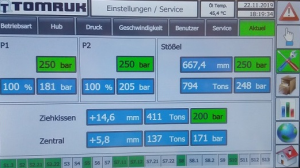

State-of-the-art control system fully adapted to your needs

Benefit from our experience as a press manufacturer. The installation of new control electronics can reveal previously hidden performance reserves of your press and continues to offer advantages in the areas of repair requirements, remote maintenance, automation and safety. It is important to us that the work carried out is sustainable. Our control system is based on the proven SIEMENS S7 press control and offers a lot of potential for expansion and individualisation to your application

ADVANTAGES:

Automation of the production process and robot implementation

Maximum efficiency and increased production

Process control and remote maintenance

Reduction of repairs

Adaptation and construction of control cabinets

Benefit from our experience as a press manufacturer. The installation of new control electronics can reveal previously hidden performance reserves of your press and continues to offer advantages in the areas of repair requirements, remote maintenance, automation and safety. It is important to us that the work carried out is sustainable. Our control system is based on the proven SIEMENS S7 press control and offers a lot of potential for expansion and individualisation to your application

Benefit from our experience as a press manufacturer. The installation of new control electronics can reveal previously hidden performance reserves of your press and continues to offer advantages in the areas of repair requirements, remote maintenance, automation and safety. It is important to us that the work carried out is sustainable. Our control system is based on the proven SIEMENS S7 press control and offers a lot of potential for expansion and individualisation to your application

ADVANTAGES:

Concept and design

Development of circuit diagrams

Installation of high-quality components

Replacement of old and defective components

Maintenance and spare parts- everything for one source

We offer a comprehensive spare parts supply for all machines entrusted to us. Due to our high vertical range of manufacture, we offer the provision of spare parts not only for our own products but also for those of other manufacturers. This is one of our greatest strengths, as everything comes from one source and you benefit from our cost efficiency and parts quality. Our own production also allows us to draw up process plans for the provision of spare parts for your production plant under the aspect of “predictive maintenance”, in which information (BIG DATA) on machine behaviour is collected and thus a probable failure can be predicted.

ADVANTAGES:

Rapid exchange in case of error

Cross-brand spare parts service

Cost efficiency with optimum quality

Recording of the parts order history to repeat orders

Avoidance of production downtime in the event of damage

With our production resources, we can support you in the event of machine breakdowns or during the maintenance / retrofitting of your system to compensate for production breakdowns. If your production facility should fail at short notice, we will ensure that you do not get delayed in delivery.

ADVANTAGES:

No delay in delivery

Exchange of spare parts can be planned

Avoidance of production downtime in the event of damage

Major renovations to increase efficiency without loss of production

Ensure safety – prevent accidents

In order to identify weak points and missing protective measures, we also offer an machine saftey inspection to ensure the safe operation of your press or production plant. All safety-relevant components are checked and any defects are rectified in cooperation with you. We also offer this service across all brands. Machine saftey inspections can also be carried out during every maintenance.

ADVANTAGES:

Guarantee of safety with production plants

Inspection, repair and replacement of all components relevant for safety

Logging of the condition as well as reminder of deadlines and dates

Machine safety inspection during maintenance or as a maintenance contract supplement

ADVANTAGES OF THE HOLISTIC TOMRUK SERVICE CONCEPT

Rapid assistance in the event of damage

We are available for you and are there for you immediately after the damage has occurred. Either via an online interface to your machine or by telephone, countermeasures are initiated.

Damage analysis

After a detailed assessment of the damage and the introduction of initial countermeasures, we will present you with several options. In most cases an adjustment of the control system is sufficient to solve the problem.

Mechanical damage

After a transmission of the damage (picture) we coordinate the countermeasures with you by telephone. If parts need to be replaced, we will support you in the dismantling process or send an intervention team to your location. At the same time we start planning the spare parts production.

Production backup

After a cost-benefit analysis, the planning of the production transfer begins. We take care of the logistics and the transport of the tool. It is also possible to specify in advance in the service contract under which conditions the parts can be manufactured.

Possibility for optimisation

While waiting for the spare part, the downtime can be used for maintenance or even for an overhaul of the system to avoid future failures.

Restarting production

The spare part is returned at the same time as your tool and we will assist you in reinstalling it. We also prepare a maintenance plan to prevent future damage or produce a spare part to be able to react perfectly to possible future damage.

YOUR SATISFACTION IS OUR GOAL

tomruk@tomruk.com

+90-(0)212-552 02 55

TOMRUK PRES A.Ş.

Çınar Cad.25

Yenibosna 34197 ISTANBUL